Other products

-

Gray Talc Powder

-

White Talc Powder

-

Bunkery Calcium Carbonate Powder

-

Coated Calcium Carbonate Powder

-

Barium Sulfate Powde

-

Calcium Carbonate Powder

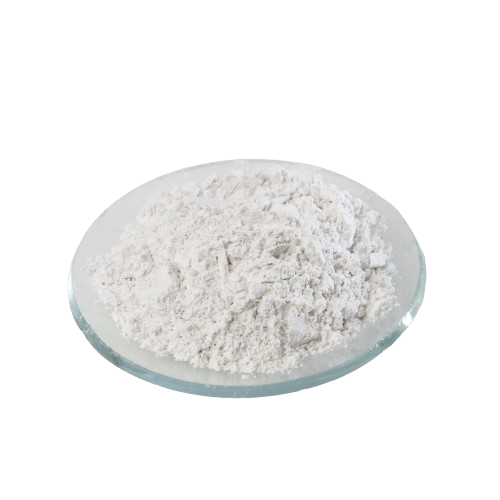

Coated Calcium Carbonate Powder

| Description | Feature |

| coated Calcium Carbonate | Material name |

| CaCO₃ | Chemical formula |

| White Powder | Physical appearance |

| Stearic acid or similar organic materials | Type of coating |

| Rhombohedral or hexagonal (depending on the mineral origin) | Crystal structure |

| About 3 (relatively soft) | Hardness (Mohs scale) |

| Decomposition at approximately 825 °C | Melting point |

| Approximately 2.7 g/cm³ | Density |

| Slightly soluble (very poorly soluble in pure water) | Solubility in water |

| Plastics, paint, coatings, rubber, paper | Main applications |

| Softening agent, lubricant, surface property and flow improver | Mechanical properties |

| Moisture absorption reduction, improved dispersion in polymers, reduced equipment wear | Special properties of Bunkeri |

| Safe for industrial use; dust inhalation should be limited | Safety |

Price inquiry and order placement

The product price varies depending on the order volume, packaging type, and shipping conditions. For an accurate price quote and purchasing consultation, please contact our experts.

We strive to offer you the best market price with the highest quality raw materials.

Description Coated Calcium Carbonate Powder

Coated Calcium Carbonate Powder Explanation

Coated calcium carbonate, also known as coated or surface-treated calcium carbonate (Coated Calcium Carbonate Powder), is a modified type of calcium carbonate designed to enhance compatibility and performance in polymer formulations. In this product, the surface of fine mineral calcium carbonate particles is coated with a thin layer of fatty acids, particularly stearic acid with the chemical formula CH₃(CH₂)₁₆COOH.

This coating reduces the hydrophilicity of the particles and increases their hydrophobicity, resulting in better dispersion and more effective interaction with hydrophobic polymers such as polyethylene (PE), polypropylene (PP), and PVC. Coated calcium carbonate is especially used in industries such as plastics, rubber, masterbatch, compounds, and PVC products. It plays a key role in improving mix uniformity, enhancing mechanical properties, reducing friction, optimizing production processes, and lowering additive consumption. These characteristics make it a highly effective and economical filler or extender in polymer product manufacturing.

Features of Coated Calcium Carbonate Powder

Significant reduction in oil absorption:

Coated calcium carbonate absorbs less oil or oily materials in the formulation, allowing materials to move more smoothly and easily during the production process. Reduced oil absorption results in better flow through equipment and molds, increasing production speed, minimizing technical issues such as blockages or machine stoppages, and improving the final product quality.

Maximum void filling:

Due to controlled particle shape and size, coated calcium carbonate can efficiently fill the spaces between polymer chains or within resin matrices. This increases density, reduces base resin consumption, and ultimately lowers production costs, making it an effective volumetric filler.

Neutral pH and non-reactive:

Calcium carbonate has a neutral pH and does not react with most chemicals in polymers and resins. This ensures chemical stability and compatibility in diverse formulations, reducing risks of degradation, yellowing, or color changes in the final product.

High hydrophobicity:

Naturally, calcium carbonate is hydrophilic and tends to absorb moisture. Coating it with fatty acids like stearic acid renders the surface hydrophobic, preventing moisture absorption in polymer compounds, reducing surface or functional defects, and enhancing resistance to environmental conditions such as high humidity.

Dust-free:

The stearate coating makes particles smoother, more slippery, and easier to mix with polymers, reducing mechanical wear on processing equipment. The surface coating also minimizes dust formation during handling or mixing, improving industrial safety and hygiene.

Polymer adhesion:

Surface modification with organic compounds such as stearic acid enhances compatibility with polymer matrices. This improves particle adhesion to polymers, increasing mechanical strength, fracture resistance, and dimensional stability of the final compound.

Uniform dispersion in polymer materials:

Coated calcium carbonate has a smooth surface and suitable coating, enabling even dispersion in polymer matrices. This prevents particle aggregation, ensuring uniform appearance and high mechanical quality in the final product.

High purity:

High-purity calcium carbonate contains minimal impurities, enhancing performance in sensitive industries such as pharmaceuticals, food, and high-quality plastics. Higher purity increases efficiency and safety in precise applications.

Improved biodegradability of plastics:

As a natural mineral, coated calcium carbonate can enhance the biodegradability of plastics, allowing plastic products to break down faster and return to nature more efficiently, reducing environmental impact and improving recyclability.

Standard and controlled particle size:

Particle size is precisely controlled for uniform distribution in production processes, improving performance, reducing interference or particle aggregation, and facilitating easier use in production lines.

Economic savings:

High-quality coated calcium carbonate reduces the need for resin in polymer formulations, achieving similar or better properties with less resin. Optimized material composition increases efficiency, reduces waste, and significantly lowers production costs.

Reason for Using Stearic Acid Coating:

Calcium carbonate is naturally hydrophilic and incompatible with organic polymers, which are hydrophobic. This incompatibility can cause issues in industrial processes, such as:

Poor dispersion in the polymer matrix

Increased friction and wear in machinery

Reduced final product quality

Stearic acid, however, has a polar head that binds to the mineral surface and a long non-polar hydrocarbon tail compatible with polymers. This effectively bridges the two materials, creating a pseudo-organic bond between them.

Coating Process of Calcium Carbonate

Calcium carbonate is one of the most widely used mineral materials globally, extensively applied in industries such as plastics, rubber, polymers, paints, compounds, and masterbatches. This mineral exists in two main forms:

Ground Calcium Carbonate (GCC): Extracted from natural sources, GCC is the result of millions of years of geological processes. It is composed mainly of sedimentary rocks formed from marine organisms such as corals and crustaceans. After extraction, it is mechanically milled to particles of specific sizes, retaining a natural crystalline structure with irregular shapes.

Precipitated Calcium Carbonate (PCC): Produced synthetically in industrial settings, PCC is made by heating limestone to obtain quicklime (CaO) and carbon dioxide (CO₂), then reintroducing CO₂ in water to produce high-purity, uniform particles. This controlled structure improves physical properties and compatibility with certain industrial formulations.

In many industrial applications, especially in the polymer industry, there is a need to enhance the compatibility of calcium carbonate with organic materials and improve dispersion in polymer matrices. Natural calcium carbonate is hydrophilic with high surface energy, whereas common polymers like polyethylene (PE) and polypropylene (PP) have low surface energy. This mismatch can cause poor adhesion, particle agglomeration, and moisture absorption in the final compound.

Coated Calcium Carbonate (CCC) is a modified version designed to enhance performance in polymer industries. The surface of calcium carbonate particles is coated with a thin layer of fatty acids, particularly stearic acid (CH₃(CH₂)₁₆COOH). This coating renders the particles hydrophobic, improves dispersion in polymers, and enhances the final product quality.

Coating Process:

A solution of stearic acid is sprayed onto dry calcium carbonate.

The mixture is then milled to create a uniform, stable coating on each particle.

The process targets a monolayer concentration (about 1%) to fully cover particle surfaces without excess. A minimal amount of free acid at the end of the process is normal and manageable with careful control.

Benefits of Coating:

Produces a white, uniform, hydrophobic mineral filler with high dispersibility in polymer matrices.

Can replace part of expensive polymers, reducing production costs.

Enhances mechanical and aesthetic properties of products.

Prevents particle agglomeration and weak points in the final material.

Reduces moisture absorption and increases storage stability.

Improves adhesion to polymers, enabling better performance.

Coating can be applied to both GCC and PCC, though high-quality GCC is most commonly used. The final coated product is smooth, uniform, and performs significantly better than uncoated calcium carbonate.

In summary, coated calcium carbonate bridges the natural structure of GCC with the advanced requirements of modern industries—a simple but effective modification making it a smart, practical, and cost-efficient filler in various industrial formulations.

Types of Coated Calcium Carbonate Powder

Coated calcium carbonate powders are produced in two main types: food-grade and industrial, each with specific characteristics and applications.

Food-Grade Coated Calcium Carbonate: This type is intended for use in pharmaceutical and food industries and must have high purity and approved edible coatings.

Industrial (Non-Food) Coated Calcium Carbonate: Industrial coated calcium carbonate powder is mainly used in plastics, rubber, paints, adhesives, resins, and construction. In this type, industrial stearic acid or non-food surfactants are typically used as the coating agent.

What is the difference between coated and uncoated calcium carbonate?

Coated calcium carbonate (Coated Calcium Carbonate) has significant differences compared to ordinary (uncoated) calcium carbonate, making it a superior choice in many industrial applications, especially in polymer and plastic industries.

Ordinary calcium carbonate is naturally hydrophilic, which makes it incompatible with polymers such as polyethylene (PE), polypropylene (PP), or other organic materials. This incompatibility can result in poor dispersion in the polymer matrix, particle agglomeration, weak mechanical properties, high moisture absorption, and ultimately reduced quality of the final product.

In coated calcium carbonate, particles are covered with a thin layer of fatty acid (usually stearic acid). This surface coating eliminates the hydrophilic nature of the particles, making them hydrophobic and highly compatible with nonpolar polymers. As a result:

Better compatibility with polymers: The hydrophobic coating allows coated calcium carbonate to mix effectively with nonpolar polymers like PE and PP.

Uniform dispersion in the polymer matrix: The modified surface prevents particle agglomeration, improving both the appearance and mechanical quality of the product.

Increased adhesion to the polymer matrix: The fatty acid coating enhances bonding between calcium carbonate particles and polymers, increasing tensile and compressive strength and reducing brittleness.

Reduced moisture absorption: The surface coating prevents moisture uptake, which is crucial in sensitive industries such as cable, pipe, and industrial components production.

Improved thermal properties: The stearic acid coating provides surface insulation, enhancing thermal stability during extrusion and molding processes.

Enhanced production efficiency: Coated calcium carbonate reduces process issues (like clogging or instability in production lines) and improves production speed and quality.

Resin savings: Better compatibility and uniform dispersion allow for higher calcium carbonate loading, reducing the amount of base resin needed.

Overall, coated calcium carbonate, with its simple yet effective surface modification, performs far better than uncoated calcium carbonate and is an intelligent choice for advanced industrial applications.

Applications of Coated Calcium Carbonate in Various Industries

Coated calcium carbonate is specifically used in the plastics, rubber, masterbatch, compound, and PVC product industries. It plays a key role in:

Improving uniformity of mixing

Enhancing mechanical properties

Reducing friction

Optimizing production processes

Decreasing the consumption of additives

These characteristics make it a highly effective and economical filler or extender in the production of polymer products.

Plastics and Polymer Industry

Coated calcium carbonate is a key additive in the plastics industry, acting as an optimal filler that significantly improves the technical performance of polymer compounds. It delivers excellent results in products such as polyethylene films, plastic containers, injection-molded parts, masterbatches, and granules. Its uniform dispersion in the polymer structure prevents particle agglomeration and enhances compatibility with polymer matrices. This not only improves the final product’s appearance but also facilitates smoother molding processes. Additionally, using coated calcium carbonate reduces the consumption of expensive resins, lowering production costs. It also increases hardness, dimensional stability, thermal resistance, tensile strength, and impact resistance, making it highly valuable for industrial and packaging applications. Overall, coated calcium carbonate balances quality, performance, and cost-efficiency, making it a smart choice for professional manufacturers.

Wire and Cable Industry

In electrical wire and cable production, coated calcium carbonate serves as an excellent filler in cable insulation. It reduces moisture absorption, enhances heat and fire resistance, improves mechanical properties, and facilitates extrusion. Therefore, high-quality coated calcium carbonate powder with competitive pricing is in demand among cable manufacturers.

Paint and Coating Industry

In the production of architectural and industrial paints, coated calcium carbonate acts as a strategic filler with superior performance compared to uncoated types. It improves coverage, adhesion to surfaces, durability, and longevity of coatings. Its low oil absorption reduces the need for expensive resins, leading to significant cost savings. Additionally, its matting effect and pigment dispersion create a more uniform and high-quality finish, making it one of the most important fillers in paint, plastic, and rubber industries.

Adhesives, Sealants, Rubber, and Foam Industries

Coated calcium carbonate is widely used as a mineral filler due to its surface properties. Stearate coating makes it hydrophobic and compatible with polymer resins, enhancing mechanical and processing properties. In adhesives and sealants, it improves adhesion, reduces shrinkage, increases moisture and chemical resistance, and extends product lifespan. In rubber, it lowers viscosity and improves processability, enhancing production efficiency. In foams, EVA, and lightweight parts, it promotes uniform cell structure, reduces weight, and increases elasticity and appearance quality. This makes coated calcium carbonate both a technical and economic solution in polymer and chemical industries.

PVC, Doors, Windows, and Pipes

In UPVC doors and windows, sewage pipes, and electrical cables, coated calcium carbonate increases thermal and mechanical resistance of the products.

Paper and Cardboard Industry

In papermaking, coated calcium carbonate improves the quality of paper and cardboard by increasing whiteness, surface smoothness, and thickness uniformity, while enhancing printability. The coating reduces ink absorption, providing sharper and more durable prints. Its better water resistance compared to uncoated types makes it ideal for packaging papers and sturdy cardboard, improving strength and longevity.

Note: Coated calcium carbonate not only enhances technical performance but also provides an economical and environmentally friendly solution, making it increasingly popular in masterbatches, plastic pipes, polymer sheets, automotive parts, and packaging industries.

How to Evaluate the Quality of Coated Calcium Carbonate Powder

The quality of coated calcium carbonate powder can be assessed through:

Chemical Analysis (XRF): Determines the purity and elemental composition.

Water Contact Angle Measurement: Evaluates the hydrophobicity of the coated particles.

Particle Size Distribution (PSD): Checks uniformity and size control of the powder.

Process Behavior Tests: Observes how the powder performs during manufacturing processes.

Practical Tests with Polymers: Mixing the powder with polymers and assessing the final product’s performance to ensure functionality and compatibility.

Key Points for Purchasing Coated Calcium Carbonate

Chemical Analysis

Calcium Content (Ca): Measured by reacting the sample with an acid like hydrochloric acid (HCl) and determining the volume of CO₂ released. This indicates the calcium concentration in the powder.

Carbonate Content (CO₃): Determined by reacting with acids; the amount of CO₂ released reflects the carbonate percentage.

Physical Analysis

Particle Size (Particle Size Analysis): Measures the distribution of particle sizes using methods like sieving or light scattering to ensure uniformity.

Density: Determined by measuring the sample’s weight and volume, helping to understand its physical characteristics.

Thermal Analysis

Thermogravimetric Analysis (TGA): Examines weight changes under varying temperatures, providing information about thermal stability and volatile components (like CO₂).

Decomposition Temperature: The temperature at which CaCO₃ decomposes into CaO and CO₂, which helps assess purity.

Color and Appearance Analysis

Color Measurement: Uses spectrophotometers to evaluate the color, important for applications in paints and coatings requiring specific visual properties.

Impurity Determination

Presence of Impurities: Detects substances such as silicates, iron, magnesium, or organics via methods like Atomic Absorption Spectroscopy (AAS) or chromatography.

Stability and Chemical Behavior

Acid Reaction: Reactivity with acids like HCl can indicate stability and composition.

Solubility: The solubility of calcium carbonate in water or specific conditions affects its performance in applications like masterbatches or plastics.

Coated Calcium Carbonate Price

Isfahan province is one of the main production centers of coated calcium carbonate in Iran. The presence of high-quality mineral resources and strong industrial infrastructure makes the price of this product in Isfahan competitive and reasonable. Companies like Sepahan Narm Powder offer high-quality coated calcium carbonate at attractive prices through direct supply.

The price of this material is influenced by factors such as purity level, particle size (mesh), and the type of coating agent (e.g., imported stearic acid). For price inquiries and purchasing consultation, it is recommended to contact the company’s sales experts.

Purchasing Coated Calcium Carbonate

If you intend to purchase coated calcium carbonate powder for your production or industrial unit, Sepahan Narm Powder is ready to supply this product in various volumes according to your needs. The benefits of buying from this company include:

Guaranteed quality and consistency in the product formulation

Fast delivery across the country

Secure and standard packaging

Free consultation to choose the most suitable powder type for your application

Conclusion

The market for both uncoated and coated calcium carbonate is highly active due to their wide applications across various industries. Coated calcium carbonate, with features such as water repellency and better dispersion in polymers, is an ideal choice for the polymer industry. Purchasing directly from a reputable manufacturer like Sepahan Narm Powder ensures product quality, cost savings, and access to a consistent and uniform material.

1 review for Coated Calcium Carbonate Powder

narmpowder –

سلام خسته نباشید من ازتون کربنات کلسیم پوشش دار رو برای ازمایشگاه خریدم و قیمتش به نسبت همکاراتون خیلی مناسب بود.