Other products

-

Gray Talc Powder

-

White Talc Powder

-

Bunkery Calcium Carbonate Powder

-

Coated Calcium Carbonate Powder

-

Barium Sulfate Powde

-

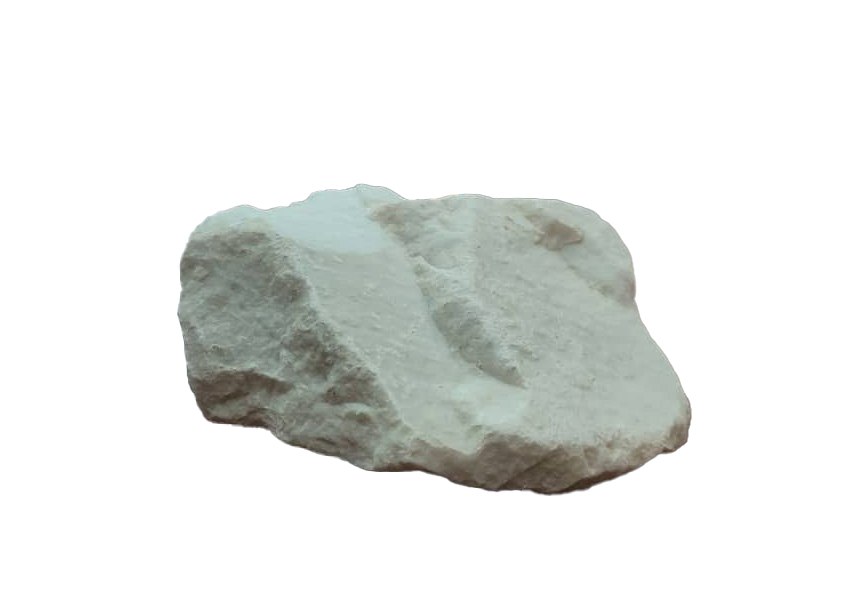

Calcium Carbonate Powder

Calcium Carbonate Powder

| Description | Feature |

| CaCO₃ | Chemical formula |

| Limestone, calcite, marble, chalk | Other names |

| Solid | Physical appearance |

| White to grayish | color |

| 1340 °C (under high pressure) | Melting point |

| 100.09 g/mol | Molecular weight |

| Cement production, plastic manufacturing, pharmaceuticals, glass industry, water treatment, etc. | Applications |

| Slightly soluble (0.0013 g/100 mL at 25 °C) | Solubility in water |

| Reaction with acids (produces carbon dioxide and water) | Chemical property |

| Rocks (limestone, marble, calcite), minerals | Occurrence |

| Extraction from limestone mines and processing it | Preparation process |

Price inquiry and order placement

The product price varies depending on the order volume, packaging type, and shipping conditions. For an accurate price quote and purchasing consultation, please contact our experts.

We strive to offer you the best market price with the highest quality raw materials.

Description Calcium Carbonate Powder

Calcium Carbonate Powder Description

Calcium carbonate (CaCO₃) is one of the most abundant mineral compounds in the Earth’s crust, making up over 4% of it, and is found extensively worldwide. Naturally, it occurs in rocks such as limestone, gypsum, and marble, which are formed from the fossilized remains of marine organisms like shells, snails, and corals over millions of years. Although these natural forms are chemically identical, they differ in properties such as purity, whiteness, thickness, and uniformity.

Calcium carbonate powder is a white, odorless, and neutral material obtained by extracting and grinding mineral rocks like calcite, aragonite, and marble. It is available in various particle sizes. Due to its unique characteristics—including high whiteness, suitable purity, uniform distribution, and chemical stability—it is recognized as one of the most useful and widely applied mineral materials across various industries. Calcium carbonate produced in Isfahan is an example of a high-quality domestic product, made using the region’s rich mineral resources and advanced processing technologies. Its affordable price, abundance in natural sources, and availability from reputable brands make it highly valued by both domestic and international manufacturers.

Despite its advantages, safety precautions are important, as inhaling fine particles of this powder may irritate the respiratory system and cause lung discomfort. Therefore, observing safety principles during handling, transport, and storage of calcium carbonate is essential.

Calcium carbonate crystals, known as calcite, play an important role in daily life. These crystals typically appear in a rhombohedral shape, a result of a property called cleavage. Cleavage refers to a crystal’s tendency to break along planes where atomic bonds are weaker, creating defined angles and smooth surfaces. Calcite is distinguished by having three different cleavage directions, a unique feature among crystals. Calcite appears in a wide range of colors, but the most common forms are white or transparent. Another notable property of calcite is double refraction or birefringence. This occurs when a light beam enters the crystal and splits into two separate beams instead of passing straight through—one travels faster and the other slower. These beams are refracted at different angles relative to the surface, creating two distinct optical paths. This double refraction makes calcite valuable and useful for many optical and photonic applications.

Calcium Carbonate Powder Properties

Properties such as filling capability, suitable oil absorption, antacid behavior, and improvement of mechanical properties make calcium carbonate powder widely used in various industries, including paper, paint, plastics, rubber, construction, pharmaceuticals, and cosmetics. Additionally, it serves as a source of calcium in animal feed, poultry nutrition, and is used in the food industry and production of cellulose-based products. Other key features of calcium carbonate include:

Varied particle sizes tailored to consumer needs (micronized and high mesh).

High whiteness suitable for use in paint, paper, and PVC industries.

Controlled oil absorption for better compatibility with polymers.

Low moisture content to prevent interference with the production process.

Low solubility providing stability under different environmental conditions.

Applications of Calcium Carbonate in Various Industries

Calcium carbonate powder is used in many fields for diverse applications. The most important uses are described below:

Paper, Paint, Plastic, and Polymer Industry:

Calcium carbonate powder is one of the most widely used mineral materials in the paper, plastic, paint, and coating industries. In papermaking, it acts as a filler and coating agent, improving whiteness, smoothness, surface evenness, and light diffusion, thus enhancing paper quality. As a low-cost filler, it can constitute up to 30% of the paint weight, contributing to brightness and uniformity. It is also used in adhesives and sealants. In the plastics industry, calcium carbonate as a filler reduces the consumption of expensive resins, increases hardness, and improves the stability of products like polyethylene, polypropylene, and PVC, helping to lower production costs. In the production of construction and industrial paints, it improves coverage, abrasion resistance, and gloss, enhancing quality and reducing final product price. Overall, due to its favorable physical and economic properties, calcium carbonate plays a key role in improving quality and reducing production costs across industries.

Construction Industry:

Calcium carbonate plays a vital role in construction. It is used both as an independent building material such as marble and limestone, and as a primary raw material in cement production. Additionally, calcium carbonate powder is used in mortars, enhancing strength and adhesion for bricks, concrete blocks, stones, tiles, ceiling zones, and even in rubber-based construction compounds. These properties make it an indispensable mineral in modern construction.

Animal Feed:

One of the major uses of calcium carbonate is in animal and poultry feed. Specially formulated feed-grade calcium carbonate helps increase dietary calcium, which is crucial for bone health, animal growth, and particularly for enhancing egg production in poultry. As a vital calcium source, it supports bone development, nerve function, and milk and egg production. Since common farm feeds like grains often lack sufficient calcium, adding feed-grade calcium carbonate is essential to meet animals’ calcium requirements.

Pharmaceutical and Cosmetic Industry:

Calcium carbonate powder, due to its whitening properties, soft texture, and high skin compatibility, is used as a natural filler and whitener in cosmetics and personal care products such as creams, face powders, and lotions. It absorbs excess moisture and reduces oiliness, making it suitable for oily and sensitive skin. Combined with titanium dioxide, it enhances coverage, brightness, and color uniformity in cosmetic products. Additionally, calcium carbonate is used in calcium supplement tablets and toothpaste as a filler, softener, and calcium source, contributing to safe, effective, and skin-friendly formulations.

Water Treatment:

Calcium carbonate (CaCO₃) is an effective mineral in water treatment due to its chemical and physical properties. One of its main uses is pH adjustment in acidic waters; its mild alkalinity neutralizes acids and prevents equipment corrosion. It is also employed in lime-soda processes to reduce water hardness by precipitating calcium and magnesium ions. Other roles include aiding sedimentation of suspended particles, adsorbing heavy metals like lead and iron, and reducing pipe corrosion by forming a protective layer. These features make calcium carbonate a widely used and effective material in drinking water, industrial water, and wastewater treatment.

Types of Calcium Carbonate Crystals

Calcium carbonate is one of the most important natural mineral compounds, found in nature in three main crystalline forms: calcite, aragonite, and vaterite. These forms differ in the geometric arrangement of calcium and carbonate ions, which leads to distinct physical properties. All of these minerals form naturally.

Chemically, pure calcium carbonate appears as a white powder and decomposes into calcium oxide (CaO) and carbon dioxide gas (CO₂) when heated.

Calcium carbonate extracted from mines initially arrives at factories as large lumps. These lumps are crushed in industrial crushers and mills and then ground to different particle sizes. Coarser grades are used in applications such as road base construction, while micronized powders are used for more precise industrial purposes.

One widely used form is coated (or “treated”) calcium carbonate, which is coated with stearic acid to impart hydrophobic (water-repellent) properties. This type is especially useful in specialized applications, such as in the polymer and plastic industries.

Calcite (کلسیت)

Calcite is one of the most common and stable forms of calcium carbonate (CaCO₃) in nature.

Appearance: White or colorless crystals, sometimes transparent

Specific gravity: ~2.71

Crystal system: Trigonal

Forming environments: Sedimentary rocks like limestone, metamorphosed limestone forming marble, mineral veins from hot springs, cave formations like stalactites and stalagmites

Key points:

Most common natural form of calcium carbonate

Rhombohedral crystal structure

Most stable phase at normal temperature

Uses: Production of GCC powders, construction materials, quicklime, and hydrated lime

Biological importance: Forms shells of many marine organisms such as plankton, mollusks, snails, and other soft-bodied animals

Aragonite (آراگونیت)

Aragonite is another mineral form of calcium carbonate with a different crystal structure from calcite.

Appearance: Colorless to light yellow crystals

Specific gravity: ~2.93

Crystal system: Orthorhombic (angular, right-angled crystals)

Key points:

Orthorhombic crystal structure

Less stable at room temperature (can transform into calcite)

Found in shells and corals

Uses: Biomedical applications and synthetic biological structures

Difference from calcite:

Only differs in crystal structure

Less stable and can convert to calcite under certain conditions

Precise identification requires optical or X-ray tests

Forming environments:

Marine sediments

Skeletons of some marine animals

Hot springs and specific aquatic environments

Vaterite (واتریت)

Vaterite is the third and least stable crystalline form of calcium carbonate, much rarer in nature than calcite and aragonite.

Appearance: Usually very fine crystals

Stability: Unstable; readily converts to calcite or aragonite under natural conditions

Crystal system: Hexagonal

Key points:

Rarest crystalline phase

Unstable, quickly transforms into calcite or aragonite

High potential in pharmaceuticals, especially for targeted drug delivery

Forming environments:

Specific aquatic environments

Certain biological systems or special sediments

Presence is usually transient due to its high instability; it eventually converts to more stable forms over time

Edible (Food-Grade) vs. Industrial Calcium Carbonate

Another way to classify calcium carbonate is based on its intended use: food-grade (edible) calcium carbonate and industrial calcium carbonate.

Food-Grade Calcium Carbonate

Purity: Very high, over 99%

Quality control: Strictly monitored for contaminants, heavy metals, and microbial impurities

Applications:

Production of human and animal calcium supplements

Antacids

Chewing gum

Fortified flours and foods

Regulatory compliance: Produced under strict standards with FDA approval and in accordance with global food safety regulations due to the high sensitivity of consumption

Industrial Calcium Carbonate

Grades: Available in various mesh sizes (400–3000)

Types: GCC (Ground Calcium Carbonate) or PCC (Precipitated Calcium Carbonate)

Applications:

Plastics & Rubber: Acts as a filler to improve hardness and reduce production costs

Paint & Coatings: Helps adjust viscosity, improve coverage, and enhance final product quality

Construction & Cement: Increases volume, strengthens material, and provides cost-effective solutions for building projects

In summary, the main difference lies in purity and regulatory standards for food-grade calcium carbonate versus physical properties and cost-effectiveness for industrial applications.

Important Points When Purchasing Calcium Carbonate

Paying attention to the following points can help you make the best choice when buying powdered calcium carbonate:

Check Type and Particle Size

Determine the intended application before purchase to select the appropriate particle size.

For plastics, finer mesh (higher mesh numbers) is generally preferred, while for construction, coarser mesh (lower mesh numbers) is more suitable.

Compare Quality and Price

Calcium carbonate prices vary depending on purity, particle size, and processing method.

Always evaluate price alongside technical specifications to make an informed choice.

Choose a Reliable Manufacturer

One of the most important factors is selecting a trustworthy manufacturer with a proven track record.

Sepahan Narm Powder Company, with over two decades of experience in mineral powder production, is a reputable name in this field.

Obtain Analysis and Sample Before Purchase

Request a laboratory analysis before placing an order to ensure product quality and compatibility with your production requirements.

Pay Attention to Packaging and Storage Conditions

Calcium carbonate powder should be packaged in moisture-resistant bags suitable for industrial storage.

Sepahan Narm Powder provides the product in standard, durable packaging to maintain quality.

Purchasing Calcium Carbonate Powder in Isfahan

If you are looking to buy high-quality calcium carbonate in Isfahan at a reasonable price, Sepahan Narm Powder Company is a reliable choice. Using advanced equipment, high-quality raw materials, and a specialized team, the company produces various types of calcium carbonate powder with uniform particle size and high purity.

Their products are tailored to the needs of different industries, including industrial, food-grade, coated, or uncoated types. Purchases come with competitive pricing, technical consultation, and nationwide delivery. For more information on availability and pricing, contact the sales experts at Sepahan Narm Powder today.

Calcium Carbonate Price

The price of calcium carbonate depends on several factors, including particle size (mesh), purity level, intended application (industrial or food-grade), and processing method. Typically, powders with finer mesh and higher purity—used in sensitive industries like paints or pharmaceuticals—are priced higher than general or construction-grade types.

Other factors affecting the price include the source location, transportation costs, and order volume. Sepahan Narm Powder Company offers high-quality products at competitive prices, making it one of the best options for purchasing calcium carbonate in Iran. For a precise quote and up-to-date price list, you can contact the company’s sales department directly.

Summary

Purchasing calcium carbonate is an important decision for many manufacturing industries, as it serves as a fundamental component in the formulation of various products. Given its diverse applications and the direct impact of quality on the final performance, choosing a reputable manufacturer—such as Sepahan Narm Powder Company, with a proven track record in producing high-quality calcium carbonate powder—can ensure optimal results in the production process.

Reviews

There are no reviews yet.